[罗戈导读]仓库实现自动化,不足为奇。从亚马逊到耐克的公司已经开始使用货物到人的拣货解决方案,其中机器人将货物送到人工操作员面前

[罗戈导读]仓库实现自动化,不足为奇。从亚马逊到耐克的公司已经开始使用货物到人的拣货解决方案,其中机器人将货物送到人工操作员面前

Crown Equipment呼吁使用新型的“货到人”的机器人系统

2020年9月19日

仓库实现自动化,不足为奇。从亚马逊到耐克的公司已经开始使用货物到人的拣货解决方案,其中机器人将货物送到人工操作员面前。

Crown.png

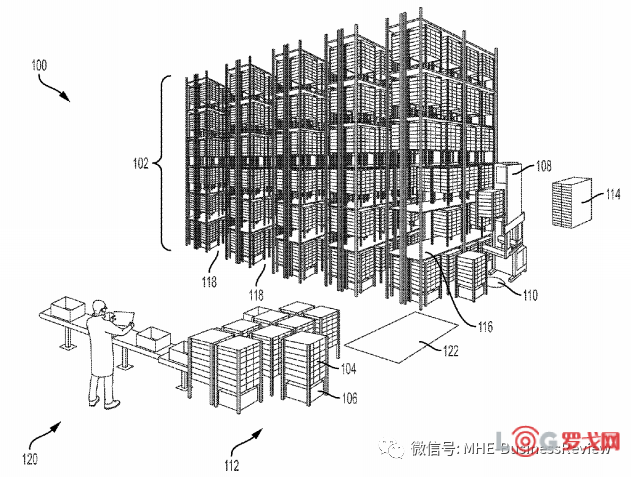

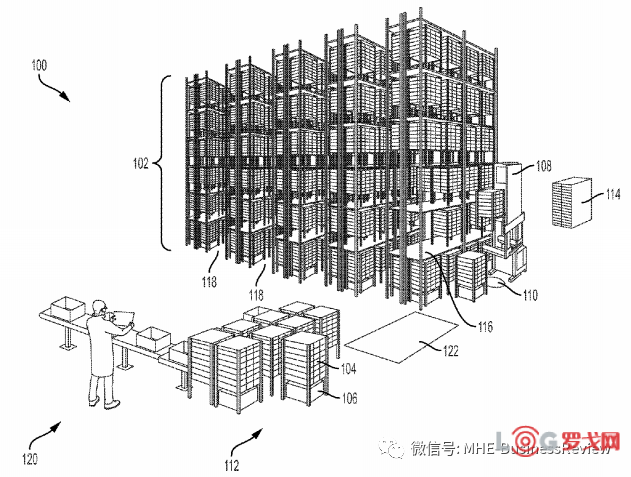

但是,Crown Equipment Corporation在本周提交的专利申请中称,这些类型的解决方案中的许多解决方案并未充分利用仓库中的空间。Crown提出的新的解决方案将充分利用多层货架系统,为自动化环境奠定了基础。

该系统依赖于两辆同时工作的车辆:一辆进行拾取(上图中的108),另一辆进行运输(上图中的106)。

“与其将移动存储单元专门运输到地面位置上,不如将存储单元运输器与取放车辆协调,以提供对存储单元运输器无法直接到达的存储区,实现自动或半自动送达,”专利内容中提及。

根据Crown的说法,该系统旨在将可移动存储单元(上图中的104)从货架系统运送到人工的拣选处,并用于存储各种货物。

由于运输机是从下方搬运存储单元的,因此不需要依靠拣选车来运输地面上的单元。根据该专利,这意味着仓库可以将其移动速度更快把货物放在货架系统的底部,以加快进出速度。

该专利解释说,存储单元运输机是自动的,但取放车可以手动操作,也可以是部分或完全自动的,并补充说,“这是任何类型的常规或尚待开发的能够移动车辆都可以完成的。实现多级货架系统中的单元存储。”

仓库管理系统将协调车辆的移动。

原文:

Crown Equipment argues for new automatedgoods-to-person robotic system

September 19, 2020

The automation of a warehouse is, at this point, nothing surprising. Companies from Amazon to Nike have started using goods-to-person picking solutions, where robots bring inventory to a humanoperator.

crown.png

But many of these types of solutions don't take full advantage of the space in a warehouse, Crown Equipment Corporation argued in a patent application filed this week. Crown made the case for anautomated environment that also takes advantage of a multilevel racking system.

The system relies on two vehicles workingin tandem: one to pick (108 in the image above), and one to transport (106 inthe image above).

"Rather than transporting mobile storage units ... exclusively to floor-level locations, a storage unit transporter can coordinate with a pick-place vehicle to provide automated orsemi-automated access to storage bays not directly accessible to the storage unit transporter," the patent reads.

The system is designed to carry mobile storage units (104 in the image above) from the racking system to the human picker and is designed to store a variety of goods, according to Crown.

Because the transporter carries the storage unit from under neath, it won't need to rely on the picking vehicle for units onthe ground level. This means a warehouse could put its faster-moving inventory on the bottom of the racking system to allow for faster access, according tothe patent.

The storage unit transporter is autonomous,but the pick-place vehicle could be manually operated, or partially or fully autonomous, the patent explains, adding that it is "any type of conventional or yet-to-be-developed vehicle capable of placing mobile storage units in the multiple level racking system."

The warehouse management system would coordinate the movement of vehicles.

UPS卖掉货运后,FedEx也考虑剥离货运,全球公路货运寒冬?

4918 阅读

公交车送快递,邮政、顺丰、京东物流等巨头纷纷入局

2417 阅读

41页PPT深度解读京东物流一体化供应链模式!

1475 阅读8家快递被曝有一半“向上取整”!快递违规收费全清单!

1450 阅读京东物流智狼机器人跑向全国!拣货最快秒级

1283 阅读DPD英国与Yeep!达成战略合作 将新增8000个自提柜

1028 阅读浙江省开通首条往返乌兹别克斯坦全货机航线

1049 阅读轩航国际航空物流(深圳)有限公司完成2000万人民币A轮融资

1006 阅读马士基与沙特邮政建立战略合作伙伴关系

938 阅读链库与新疆海鸿冷链达成战略合作

931 阅读